Body Blanks they were called. They began as a sheet of 36 (beer and soda, anyway) and were sliced to size to create 3 piece lidded cans. Inspected and approved by various folks throughout the chain of the canning process, steel body blanks were passed like stiff sheets of paper between union co-workers and state approval boards. Who would have dreamed that a 5 x 7 sheet of steel could hold so much graphic beauty and be instructional at the same time? Fashionable (according to the era) and functional. Body blanks were miniature metallic masterpieces of brand imagery, eye-catching graphics and most importantly, the fine print. (as they say, the difference is in the details.)

Body Blanks they were called. They began as a sheet of 36 (beer and soda, anyway) and were sliced to size to create 3 piece lidded cans. Inspected and approved by various folks throughout the chain of the canning process, steel body blanks were passed like stiff sheets of paper between union co-workers and state approval boards. Who would have dreamed that a 5 x 7 sheet of steel could hold so much graphic beauty and be instructional at the same time? Fashionable (according to the era) and functional. Body blanks were miniature metallic masterpieces of brand imagery, eye-catching graphics and most importantly, the fine print. (as they say, the difference is in the details.)

Most often, it was the fine print that would cause a can to be rejected or changed. Sure, maybe the colors didn’t align properly or weren’t the right color, no biggie. That was dialed in via the printing press operator. But if the printed information wasn’t spot on, a press change to reprint new sheets was ordered.

Precisely why union employees held onto them during their careers. Usually stacked in a manila envelope a few inches thick and kept for reference and proofs. These stacks required serious forearm strength to lift from a file folder,. as an envelope might weigh 5-10 lbs.!

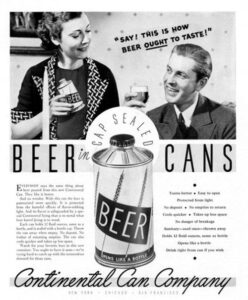

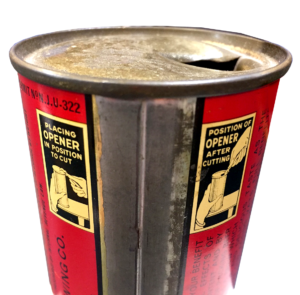

In 1935, the Krueger Brewing Co. of Newark, NJ was one of the first pioneers to attempt canning their beer. In case it WASN’T successful, they shipped their first batch out of their home territory down to Richmond, Virginia. Taking up 54% less shelf space and weight than a bottle does, and immune to being skunked by light, why wouldn’t they be successful? But these flat-top cans required specialized canning lines to fill. For brewers that didn’t want to invest, or were too small, they offered cap-sealed cans. These flowed through existing BOTTLING lines, and had a distinctive cone shaped spout (like the old brake fluid or HEET antifreeze cans) that could also be capped and even resealed. Due to pressure issues, they had a concave tin bottom lid so the contents wouldn’t spray the consumer.

In 1935, the Krueger Brewing Co. of Newark, NJ was one of the first pioneers to attempt canning their beer. In case it WASN’T successful, they shipped their first batch out of their home territory down to Richmond, Virginia. Taking up 54% less shelf space and weight than a bottle does, and immune to being skunked by light, why wouldn’t they be successful? But these flat-top cans required specialized canning lines to fill. For brewers that didn’t want to invest, or were too small, they offered cap-sealed cans. These flowed through existing BOTTLING lines, and had a distinctive cone shaped spout (like the old brake fluid or HEET antifreeze cans) that could also be capped and even resealed. Due to pressure issues, they had a concave tin bottom lid so the contents wouldn’t spray the consumer.

Body blanks were used for beer, soda, food, petroleum products and so much more. If it came in a can, a body blank was used to create the container. So why am I telling you all of this? Because I’d love to know more. If you worked in a canning plant, were an inspector or proofed blanks, or held onto these steel sheets of history, I’d love to see and hear about it. I collect the stories and items from these days, and your input or stories would make my day. I’m also buying body blanks (one, or a stack full) and vintage can lids if you have them. And advertising mock-ups, foil wraps or test cans that were never filled or marketed. Recycling pays-and I’ll happily pay the postage, should we strike a deal.

Crown Cork and Seal

Reynolds Metal Comapny

Heekin Can Company (Cincinnati)

Standard tin plate company

The Export and Domestic Can company

Continental Can Company of New Jersey

Tindeco

Seattle Can company

Easton Can company-San Jose

Passiac Metal Ware Co.

New Orleans can company

Federal Can company

Gordon Can Co.-St Louis

Manion Steel barrel Co.

Eastern Shore Can Co.

- Hardesty Can Co.

Los Angeles Can company Manufacturers Can company

Southern Can company

Manhattan Can company

MacDonald manufacturing company-Limited

MacDonald manufacturing company-Limited

Gillis Manufacturing Canning Co.

Wilkes Barre Can Co.

Owens Illinois Can Co.

Whittall Can Co.

Beverage Can Division

Wooden Jacket Can Co.

Diawa Can Co.